High School Students Tour NCC Advanced Manufacturing Programs

Northern Nash High School advanced manufacturing students visited Nash Community College on Friday, February 24, 2023. During their visit, the students learned about the college’s advanced manufacturing programs and college classes they can take during and after high school.

Computer-Integrated Machining instructor Jason Brannan explained the foundational principles of machining, comparing the general concept to woodworking, except using metal. “Our students learn how to machine manually, making cuts and turning the handles themselves, before moving over to machines,” he said. “This way, you hear, see and feel how certain materials react during processes. For example, aluminum responds differently than stainless.”

Brannan graduated from NCC’s Computer-Integrated Machining program in 2015 and began as an instructor at Nash in 2021 following several years working in the field.

The Computer-Integrated Machining curriculum prepares students with the analytical, creative and innovative skills necessary to take a production idea from an initial concept through design, development and production, resulting in a finished product.

The students learned the importance of practicing on simulators to work through issues before progressing into the production environment. “After simulation, we move over to the CNC machines, learning programming by hand, writing out programs, setting up machines and tooling calculations.”

Machining graduates often work as technicians in high-tech manufacturing, rapid-prototyping and rapid-manufacturing industries, specialty machine shops, fabrication industries, and high-tech or emerging industries such as aerospace, aviation, medical, and renewable energy, and to sit for machining certification examinations.

“For those interested in pursuing an industrial degree, you might consider dual enrollment at Nash. These machining classes count for other industrial degrees here too,” Brannan said. “You can ride the bus over during fourth period and begin preparing for your career while getting both high school and college credit, tuition-free.”

Brannan told the students about a class project that is required for machining students. “As a group, you’ll come up with the concept, price it out, map out a plan and pitch it to those in leadership,” he explained. “Then, once approved, you get to create it, ordering the parts and planning it out. This experience will prepare you to do the same thing in the field.”

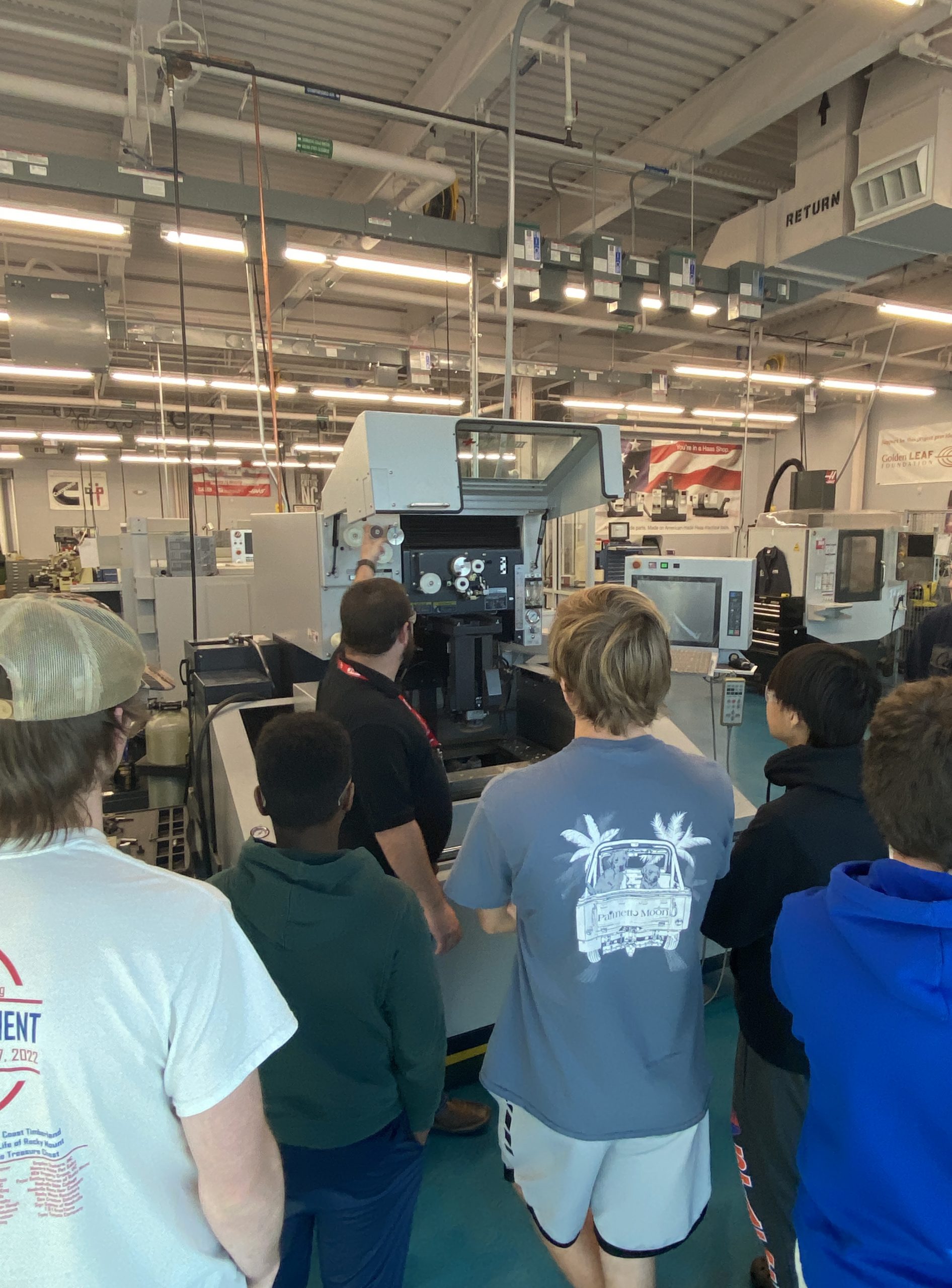

Students visited the machining floor where they learned about the computer numerical control mill, lathe and live tooling.

The students also visited the Welding program where they learned about welding and cutting processes. The Welding pathway includes courses like math, blueprint reading, metallurgy, welding inspection, and testing, preparing students with industry standard skills developed through classroom training and practical application.